Significance and design problems of pharmaceutical cold room

Pharmaceutical Cold Rooms: Unveiling Significance and Confronting Design Challenges for Optimal Medicinal Storage

Pharmaceutical cold room, also known as drug cold room, is an essential storage facility for pharmaceutical products in pharmaceutical factories, hospitals, pharmacies, disease control centers, pharmaceutical companies, etc.In order to ensure the quality and effect of medicine, it is necessary to build cold room for storage and transportation.

So people's demand for pharmaceutical cold room is gradually increasing.This article will discuss the significance of cold room for pharmaceutical factories, the structure of pharmaceutical cold room, and some key issues in the design and installation of cold room.

The significance of cold room for pharmaceutical factories

The development of the pharmaceutical industry has always been an important factor in people's healthy life. It can be said that the health of each of us is inseparable from the development of the pharmaceutical industry.

1. Since many biomedical products cannot exert their effects at room temperature, they need to be stored at a specific temperature to prolong the safe shelf life of the drug and ensure the medicinal properties and safety of the drug. Cold room plays a huge role at this time.

2.In addition, medicine is related to people's life and health. In order to meet the technical requirements of the drug supervision and management department, the construction of pharmaceutical cold room has always been one of the key construction and supervision projects for the healthy and rapid development of the pharmaceutical industry.

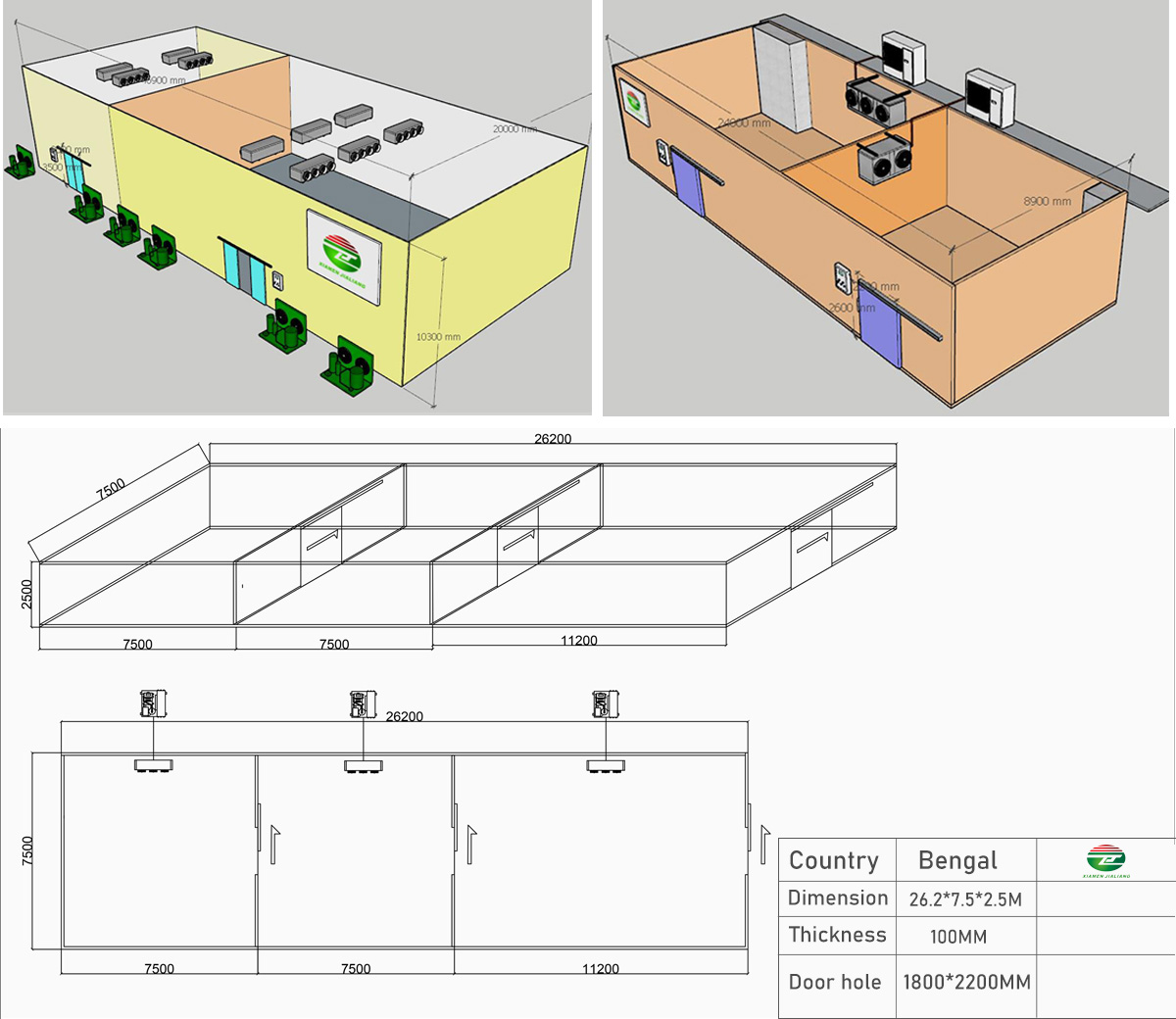

The structure of pharmaceutical cold room

The pharmaceutical cold room has the characteristics of scientific design, simple and practical, energy saving and environmental protection.

The body of the cold room is made of rigid polyurethane heat-insulating sandwich panels, which are poured and molded by high-pressure foaming technology at one time.The cold room panel is made of double-sided color steel plate, and the middle is connected with an eccentric hook and a grooved hook.

The eccentric connection method of the panel can realize the tight connection between panel and panel, and the excellent sealing can minimize the leakage of cold air and enhance the heat insulation effect.The combined use of T-shaped panels, wall panels, and corner panels also enables the cold room to be assembled in any space.

The most important thing is that the construction of pharmaceutical cold room needs to configure the cold room equipment according to the standard of "one spare and one use".For general laboratories, only one set of refrigerators, condensers and evaporators may be needed, but the pharmaceutical cold room must additionally use spare equipment.Its purpose is to activate the backup device immediately when the device fails, so that it can continue to work normally.

Design and installation problems of cold room

With the development of the pharmaceutical industry, the design and installation of cold room in pharmaceutical factories has become more and more important. Cold room in pharmaceutical factories is mainly used to store medicines and raw materials, so many factors need to be considered, such as temperature, humidity, air quality, hygiene, etc.

First of all, the cold room of the pharmaceutical factory needs to meet certain temperature requirements.The 20°C medical cool warehouse is the storage warehouse for the most common medicines.

It can be used to store all kinds of medicines that cannot be stored in a high temperature environment, but do not need to be stored in a too low temperature environment.The cool warehouse does not have too many requirements for heat preservation, but it needs to avoid direct sunlight.Generally, the temperature design of vaccine cold room is between 2°C and 8°C, which is also the common storage temperature of medicines and raw materials.However, some special vaccines, such as polio vaccines, require a temperature of -20°C, while the suitable storage temperature for active vaccines is below -15°C.

Secondly, the cold room of the pharmaceutical factory also needs to consider the humidity problem. Too high or too low humidity will lead to problems in the quality of the medicine. The humidity in the pharmaceutical cold room needs to be maintained at 35% to 75%, and the humidity should be maintained at a constant level.

The application of cold room greatly improves the safety and efficiency of medicines, ensures the timely supply of medicines, and provides great convenience for our healthy life. If you want to know more about the product, please consult us. Our website is www.coldroomjl.com.