Raiders of Meat Storage Knowledge: Refrigeration Equipment and Optimal Management

The advantage of a cold room is to maintain moderate temperature and humidity to prevent food spoilage and bacterial growth

Raiders of Meat Storage Knowledge: Refrigeration Equipment and Optimal Management

Are you a meat storage expert? If not, don't worry! We will provide you with all the information about cold room equipment and best practices in management to help you become an expert. Specific requirements must be met when storing meat to maintain its quality and safety. This is where cold room equipment comes into play. In this article, we will delve into various types of cold room for meat storage, ideal storage conditions for different types of meat, and techniques to improve overall cold room efficiency. So, get ready to explore the world of meat storage knowledge!

Cold room Equipment and Meat Storage

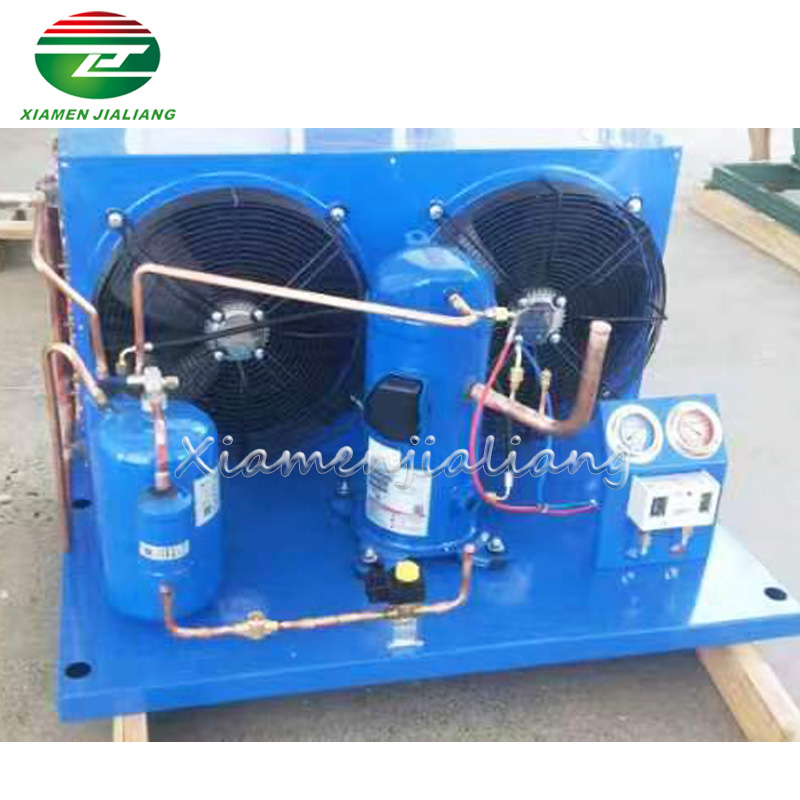

In meat storage, having the right cold room equipment is crucial for maintaining meat quality and safety. We will introduce different types of cold room equipment, such as cold rooms, freezer rooms, and blast freezers, and discuss their applications, advantages, and suitability for meat storage.

1. Cold Rooms: Cold rooms are commonly used for storing meat, seafood, and other perishable food items. They provide suitable temperature ranges, typically between 32°F to 39°F or 0°C to 4°C, for short-term preservation of food. Cold rooms are suitable for storing freshly cut meats, fish, vegetables, and other products. Their advantage lies in maintaining moderate temperature and humidity to prevent food spoilage and bacterial growth.

2. Freezer Rooms: Freezer rooms are used for freezing meat and other food items to extend their shelf life. Freezer rooms are usually maintained at 0°F (-18°C) or lower temperatures, allowing meat to be stored for an extended period. Freezer rooms are suitable for freezing meat cuts, frozen seafood, and frozen semi-finished meat products. Their advantage lies in their long-term storage capability, preserving meat quality and freshness.

3. Blast Freezers: Blast freezers are special cold room equipment used for rapid freezing of large quantities of meat and other food items. They are capable of rapidly lowering the temperature of products to extremely low freezing temperatures in a short period. Blast freezers are suitable for bulk freezing of meat cuts, quick-frozen meat products, and frozen seafood. Their advantage lies in rapid cooling, avoiding quality loss due to ice formation.

When choosing the appropriate cold room equipment, considerations should include the characteristics of the meat, storage requirements, and business scale.

Ideal Storage Conditions for Meat

During the meat storage process, different types of meat have distinct characteristics and freshness requirements. To preserve their texture and flavor, we need to adjust the storage temperature and humidity more precisely. Here are the ideal storage conditions for commonly stored meats:

1. Short-term Storage (Up to three days)

(1) Beef:

- Ideal temperature: 32°F to 39°F (0°C to 4°C)

- Ideal humidity: Relative humidity between 85% and 90%

- Freshness requirements: Beef has a higher fat content and is prone to oxidation and spoilage. Therefore, it is necessary to minimize oxygen exposure during storage. Seal beef with appropriate packaging materials to prevent oxygen ingress.

(2) Pork:

- Ideal temperature: 32°F to 39°F (0°C to 4°C)

- Ideal humidity: Relative humidity between 80% and 85%

- Freshness requirements: Pork has a higher moisture content, requiring storage at suitable temperature and humidity to prevent excessive evaporation. Proper packaging and sealing are also key to maintaining pork texture and flavor.

(3)Poultry (Chicken and Turkey):

- Ideal temperature: 32°F to 39°F (0°C to 4°C)

- Ideal humidity: Relative humidity between 85% and 90%

- Freshness requirements: Poultry is sensitive to bacteria, thus requiring rapid refrigeration at the appropriate temperature. Sealed packaging can reduce oxygen exposure and maintain poultry moisture.

(4) Lamb:

- Ideal temperature: 32°F to 39°F (0°C to 4°C)

- Ideal humidity: Relative humidity between 75% and 80%

- Freshness requirements: Lamb has lower humidity requirements and needs to be stored at the appropriate temperature to avoid spoilage. Sealed packaging and proper humidity control are crucial for maintaining lamb texture and flavor.

2. Long-term Storage

For long-term storage, meat needs to be stored at freezing temperatures of 0°F (-18°C) or below. At this temperature, meat can typically be stored for about three months. If storing for more than three months, it should be kept at temperatures below -18.4°F (-28°C), allowing storage for about six months.

In summary, different types of meat have varying ideal temperature and humidity requirements. To preserve meat texture and flavor, it should be stored within the appropriate temperature and humidity ranges, and proper packaging and sealing measures should be taken to minimize oxygen exposure.

Potential Issues in Meat Storage and Their Solutions

During the meat cold room process, several issues may arise. Here are some ways to avoid or resolve them:

1. Temperature fluctuations: Temperature fluctuations in the cold room can result in decreased meat quality and bacterial growth. To avoid this issue, ensure that the temperature control system of the cold room is functioning properly and operating within the set temperature range. Regularly check and calibrate temperature sensors and control equipment. Generally, avoid opening the cold room frequently unless necessary to maintain temperature accuracy and stability.

2. High humidity: Excessive humidity can lead to moisture accumulation on the surface of meat, promoting bacterial growth and spoilage. To address this issue, ensure that the humidity control system of the cold room is functioning properly and maintains humidity within the appropriate range. Install humidity sensors and regularly check and adjust humidity control equipment.

3.Bacterial contamination: Meat can be susceptible to bacterial contamination, leading to food safety issues. To prevent bacterial growth, regularly clean and sanitize the interior surfaces of the cold room, including walls, floors, and cold room equipment. Ensure that employees properly use personal protective equipment and follow good hygiene practices, such as handwashing and proper handling of meat.

4.Packaging issues: Improper packaging can expose meat to air, accelerating oxidation and spoilage. Choose suitable airtight packaging materials for meat storage and ensure proper sealing to prevent air leakage. Regularly inspect the integrity of the packaging and replace if any issues are found.

5.Improper inventory management: Incorrect inventory management can result in meat being stored beyond the recommended shelf life, affecting quality and safety. Implement a first-in, first-out (FIFO) inventory management system to ensure the use of older stock first and avoid accumulation of expired products. Regularly inspect and clean the inventory, promptly handling meat products approaching their expiration dates.

6.Equipment failures: Equipment failures in the cold room can lead to temperature control issues and meat damage. Conduct regular preventive maintenance and inspections to ensure the proper functioning of the equipment. Establish backup equipment or contingency plans to prevent delays and losses in case of equipment failures.

By avoiding or resolving the aforementioned issues, you can ensure optimal quality and safety of meat during the cold room process. Regular maintenance, monitoring, and employee training, along with adherence to hygiene and food safety standards, are key to effective issue resolution.