Knowledge of Screw Chiller

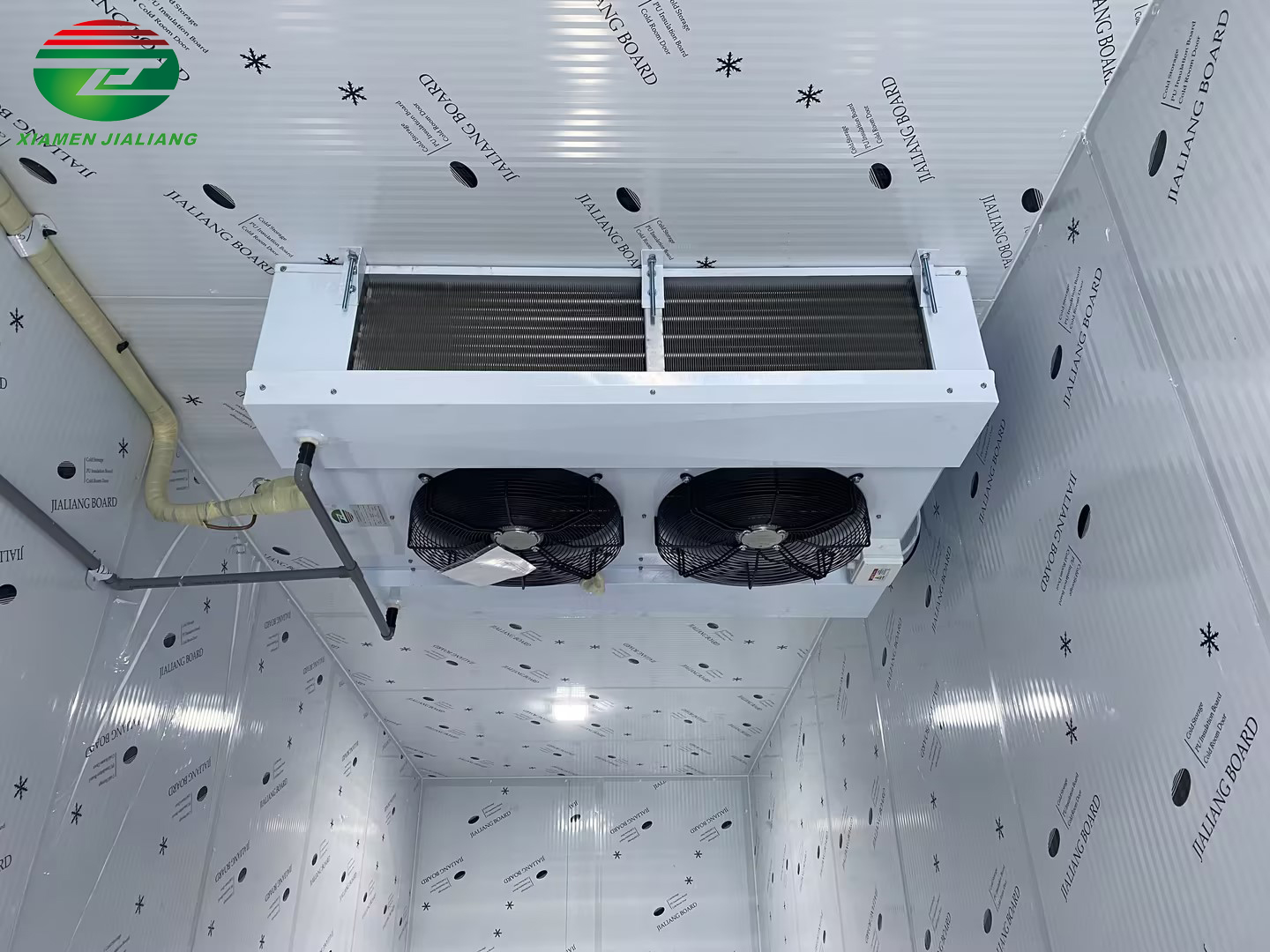

Chiller unit plays a crucial role in maintaining temperatures for processes or spaces that require controlled cooling.

Knowledge of Screw Chiller

Learned about common compressor units such as semi-hermetic compressors and scroll compressors. Today we will talk about a special screw compressor--screw Chiller. This is an industrial unit used for water supply or oil cooling. There is a lot of learning in it. The details are more complicated than those of ordinary semi-enclosed units.

The final required power of the customer's project is not only considered in terms of the number of horses, but also calculated and judged based on the amount of heat exchanged. Of course, it is also inseparable from the voltage.

We use a project from one of our clients in the Philippines as a case study.

First, the customer put forward the demand for a 50TR Chiller. In general. When customers put forward this demand, we also think that we need at least the number of pieces from the customer, and we configure and quote based on the number of pieces. The information provided by the customer is limited. We calculated based on the formula 1TR=3.5kw and judged that the customer needed a water cooler with a cooling capacity of 175kw. A preliminary conclusion is drawn that according to this demand, at least a 70-horsepower water-cooled machine with a cooling capacity of 153kw is needed.

The customer provided some of his data: compressor size 35-40KW, chilled water flow 30m3/hr, water-cooled condenser and other requirements.

Based on the size of the compressor mentioned by the customer, we can determine that the cooling capacity and power required by the customer does not match the power we configured for the customer.

Therefore, we double-confirmed with the customer whether 35~40kw refers to the power of the compressor or the cooling capacity. In addition, when the chilled water flow reaches 30m3/hr, the cooling capacity needs to be very large, which cannot be 35~40kw. A chiller with a cooling capacity of at least 175kw is required. We will slowly guide customers to provide the most accurate information. Below we will summarize what information we need during the configuration of the screw water cooler and the differences between its two forms.

Heading 1: About the main components of screw chiller

1. Compressor: The compressor is the core component of the entire refrigeration system. It is the power source for refrigerant compression. Its function is to convert the input electrical energy into mechanical energy and compress the refrigerant.

2. Shell and tube condenser: During the refrigeration process, the condenser plays the role of outputting heat energy and condensing refrigerant. After the high-pressure superheated steam discharged from the refrigeration compressor enters the condenser, all the energy absorbed during the working process, including the heat absorbed from the evaporator, refrigeration compressor and pipes, is transferred to the surrounding medium (water or air) and taken away. The high-pressure superheated vapor of the refrigerant recondenses into a liquid.

The screw chiller mainly has the above two core components that play an important role in the entire working process.

Heading 2: About the differences between the two types of screw chillers

1. Air-cooled screw chiller: The main cooling method of the air-cooled screw chiller is a combination of an aluminum fin evaporator and a fan, which is air-cooled; the screw chiller is generally placed outdoors and should be fully cooled.

2. Water-cooled screw chiller: The main machine of the water-cooled screw chiller is equipped with a cooling tower and a water pump (sometimes based on the pump provided by the customer). The heat is dissipated by the cooling tower through the continuous circulation of the pump.

Heading 3: Application scenarios of screw chillers

1. The normal temperature working range is 5 to 30 degrees, the low temperature working range is minus 5 to minus 30 degrees, and the ultra-low temperature working range is minus 30 to minus 120 degrees.

Whether there is a corrosive industry, solution contact and heat exchanger material are determined according to the actual situation.

Summarize:

Based on the above information, we have summarized below all the information needed to configure a suitable screw chiller.

1. First of all, according to the customer's local voltage usage, the screw chiller can only be used on three-phase power.

2. Need to provide output and input water temperature

3. How many cubic meters per hour is the water flow rate?

Regarding the difference between the two types of screw chillers, the cooling method of the air-cooled screw chiller host is a combination of an aluminum fin evaporator and a fan, air cooling; screw chillers are generally placed outdoors and should be fully cooled, as well as water-cooled The main machine of the screw chiller is equipped with a cooling tower and a water pump (sometimes based on the pump provided by the customer). The heat is dissipated by the cooling tower through the continuous circulation of the pump.For more information please contact us at www.coldroomjl.com