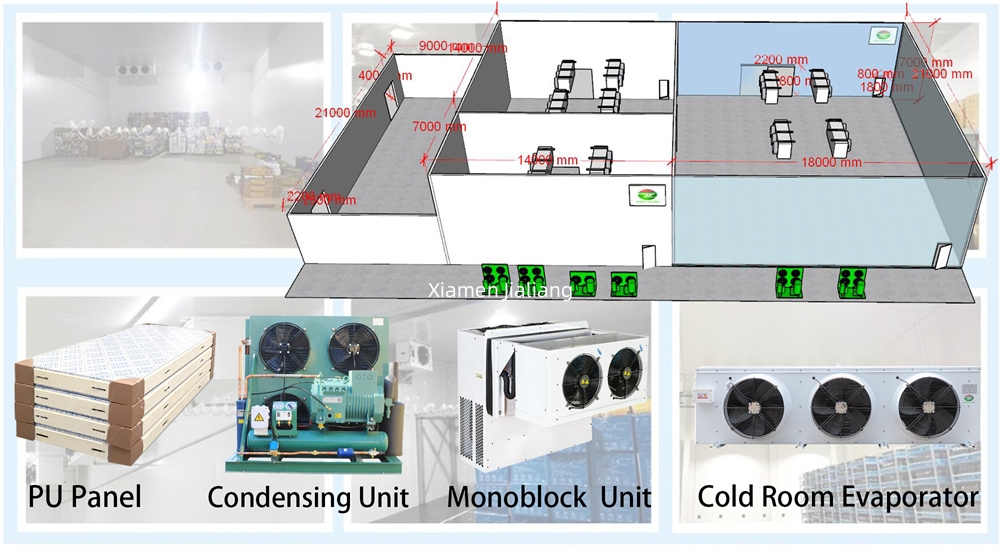

Fresh-keeping cold room for poultry and egg warehouses

Fresh-keeping Cold Room Solutions: Optimizing Poultry and Egg Warehouses for Quality Preservation

As people's requirements for food safety and quality are becoming higher and higher, the food industry is also constantly pursuing innovation and improvement. Poultry eggs are a common and important food item in the produce category, and many households cannot do without this nutrient-dense ingredient.

In order to ensure the freshness and shelf life of poultry eggs, Fresh-keeping cold room poultry egg warehouses has become an indispensable link. It is a miracle of food preservation technology. Next, let me take you walking into the world of poultry egg warehouse cold storage.

Features of Fresh-keeping cold room Poultry and Egg Warehouse

In order to ensure that poultry eggs maintain high quality and freshness during the fresh-keeping and freezing process in the warehouse, the cold room needs a series of conditions involving freezing temperature, humidity, ventilation, etc. So how does the Fresh-keeping cold room of poultry and egg warehouses keep fresh? Let's take a look together!

1. Low temperature environment

The freezing temperature of the poultry egg warehouse should be within a suitable range, usually between -2°C and -4°C. This low temperature environment helps to extend the shelf life of poultry eggs, preventing the growth of microorganisms in the eggs and food spoilage.

2. Appropriate humidity

In general, the humidity of the freezing environment should be kept low to prevent frosting and excessive evaporation on the surface of the eggs, while reducing the burden of freezing.

3. Ventilation measures

Good ventilation is the key to ensure air circulation in the cold room and avoid excessive local temperature differences. The ventilation system should ensure that the cold air is evenly distributed in every corner of the egg stack, so that the eggs are not affected by different temperature zones.

4. Quick freezing

The poultry eggs should enter the freezing process as soon as possible to prevent the water in the eggs from freezing to form large ice crystals and reduce the structural damage of poultry eggs. Rapid freezing ensures the quality and taste of poultry eggs.

Precautions for fresh-keeping and cold room in poultry and egg warehouses After understanding the characteristics of the Fresh-keeping cold room in the poultry and egg warehouse, what details can ensure the maximum function of the Fresh-keeping cold room during use? Let's learn together~

1. Pre-cooling before storage

Fresh eggs must be pre-cooled before storage. The pre-cooled eggs will quickly reach the predetermined temperature due to the low temperature of the eggs, reducing the water vapor in the cold room attached to the eggshell and reducing the growth of bacteria and other microorganisms.

Therefore, fresh eggs must have a cooling process (that is, pre-cooling) before being put into the cold storage. The pre-cooling temperature is generally 2-0°C, and the relative humidity is about 90%. After about 24 hours, the egg temperature will gradually drop before storage.

2. Arrange neatly after storage, do not lean against the wall, leave gaps

The fresh eggs must be neatly arranged in storage, and the egg boxes must not lean against the wall. A certain gap must be left between the egg boxes to facilitate air convection and reduce the growth of mold. The temperature and humidity in the cold room should be kept stable and not fluctuate.

The temperature of storing fresh eggs in the cold room is about 0°C, not lower than -2.5°C, otherwise the moisture in the eggs will freeze and the eggshell will crack. It is advisable to maintain the relative humidity in the warehouse at about 90%.

If the humidity is too high, molds are easy to reproduce; if the humidity is too low, the evaporation of water in the eggs will be accelerated and natural drying consumption will be increased. The quality of fresh eggs should be checked regularly to understand the quality changes of fresh eggs during storage and to better determine the time of storage in the future.

3. Heat up when leaving the warehouse

The temperature difference between the indoor and outdoor of the cold room is large, and the eggs should be placed in a special room to heat up when they leave the storage.

When the eggs are taken out of the warehouse without heating up, due to the low temperature of the eggs and the high outside temperature, when fresh eggs are suddenly heated, water droplets will condense on the surface of the eggshell (commonly known as "sweating"), which will easily cause the reproduction of microorganisms and lead to refrigeration and preservation its quality

broken. When the egg temperature rises to 3-4°C lower than the outside temperature, it can be released from the warehouse.

After understanding the basic situation of fresh-keeping and cold room of poultry and egg warehouses, combined with the needs of your own business, I think you must have the idea of quickly getting started with fresh-keeping and cold room for poultry and egg warehouses--come to consult us now! If you want to know more about the product, please consult us. Our website is www.coldroomjl.com