Cold room some cold knowledge

What you don't know, cold store some cold knowledge

When it comes to storing perishable goods, a cold room is an essential asset for maintaining their freshness and quality. However, have you ever wondered if a cold room can truly freeze its contents? In this article, we will delve into the factors that affect the freezing capability of a cold room and debunk common misconceptions surrounding this topic. Understanding the freezing process in a cold room is crucial for businesses in the food industry or any other sector that requires proper storage conditions. Additionally, we will provide valuable tips for maximizing the freezing capability of a cold room to ensure optimal preservation of your products. Whether you are a business owner or simply curious about the science behind cold rooms, this article will provide valuable insights into the freezing capabilities of these specialized storage facilities.

Factors that affect the freezing capability of a cold room

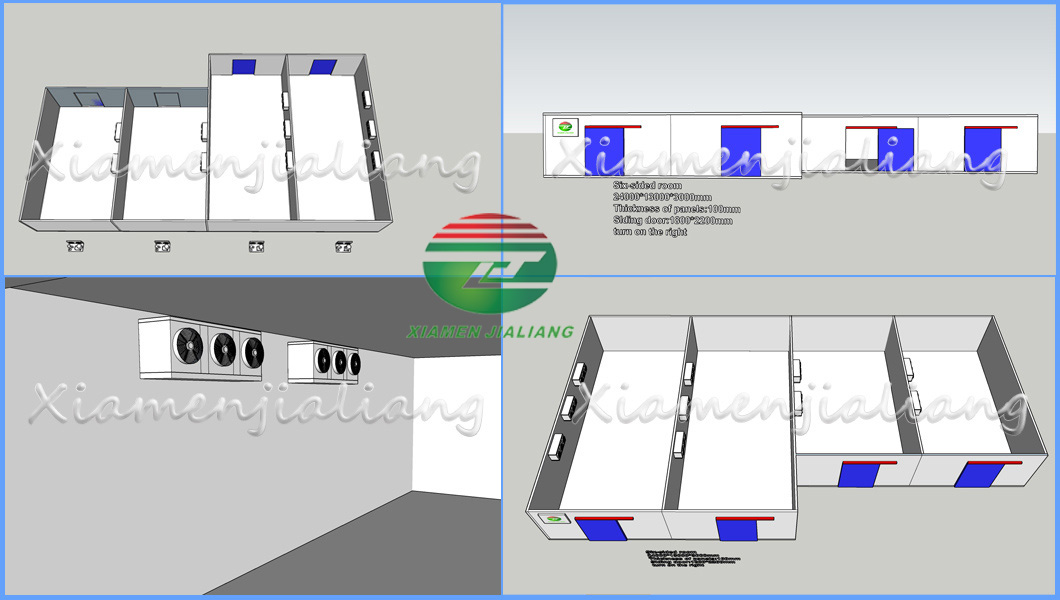

Factors That Affect the Freezing Capability of a Cold Room When it comes to maintaining the freshness and quality of perishable goods, a cold room plays a vital role in the storage process. However, several factors can influence its freezing capability, ultimately impacting the effectiveness of the cold storage system. One significant factor is the insulation of the cold room. The insulation material used in the construction of the cold room walls, ceiling, and floor plays a crucial role in preventing the exchange of heat between the interior and exterior environments. Proper insulation helps maintain the desired temperature inside the cold room, ensuring efficient freezing. Common insulation materials include polyurethane foam, polystyrene, and mineral wool. Another crucial factor is the size and layout of the cold room. The dimensions and configuration of the storage space can affect the distribution of cold air and the overall efficiency of the freezing process. An optimal layout ensures uniform temperature distribution while maximizing storage capacity. Proper shelving and racking systems also contribute to efficient airflow and easy access to stored goods. Temperature control is a critical aspect that significantly impacts the freezing capability of a cold room. A reliable and accurate temperature monitoring system, coupled with an efficient refrigeration unit, is essential. The temperature should be set according to the specific requirements of the stored products to prevent spoilage. Regular maintenance and calibration of the refrigeration system are necessary to ensure proper functioning and avoid temperature fluctuations. Humidity levels within the cold room can also affect the freezing capability. Excess moisture can lead to frost buildup on the walls and evaporator coils, reducing the efficiency of the cooling system. Proper ventilation and dehumidification mechanisms should be in place to maintain optimal humidity levels and prevent condensation.Furthermore, the quality and condition of the cold room equipment, such as compressors, evaporators, and condensers, are crucial factors. Regular inspections, servicing, and repairs are necessary to ensure that all components are functioning optimally. Any malfunctioning equipment should be promptly repaired or replaced to prevent disruptions in the freezing process.

Common misconceptions about cold rooms and freezing

Cold rooms and freezing are often misunderstood concepts, leading to various misconceptions. One common misconception is that cold rooms are solely used for storing food products. While it is true that cold rooms play a crucial role in preserving perishable goods, their applications extend beyond the food industry. Cold rooms are designed to maintain specific temperature ranges, typically between -18°C to 10°C, depending on the requirements. This controlled environment is essential for various industries, including pharmaceuticals, medical facilities, and research laboratories. In the pharmaceutical industry, cold rooms are used to store temperature-sensitive medications and vaccines, ensuring their efficacy and safety. Medical facilities rely on cold rooms to preserve blood samples, organs for transplantation, and other biological materials. Another misconception is that cold rooms are only used for freezing purposes. While freezing is one of the functions, cold rooms also provide refrigeration capabilities. This distinction is crucial, as freezing and refrigeration serve different purposes. Freezing is primarily used for long-term storage, while refrigeration is employed to maintain freshness and extend the shelf life of products without freezing them. Furthermore, some people believe that cold rooms are energy-consuming and environmentally unfriendly. However, advancements in technology have led to more energy-efficient cold room systems. These systems incorporate insulation materials, such as polyurethane foam, which minimize heat transfer and reduce energy consumption. Additionally, the use of eco-friendly refrigerants, such as hydrofluorocarbons (HFCs), has significantly reduced the environmental impact of cold rooms. It is important to debunk these misconceptions to fully understand the benefits and versatility of cold rooms. By providing a controlled environment, cold rooms ensure the integrity and quality of various products. Whether it's preserving food, storing pharmaceuticals, or maintaining research specimens, cold rooms play a vital role in multiple industries.

Understanding the freezing process in a cold room

Understanding the freezing process in a cold room is essential for various industriesthat require precise temperature control to preserve and store products. A cold room is a specially designed space that maintains low temperatures to prevent spoilage and extend the shelf life of perishable items. This article will delve into the intricacies of this process, highlighting its significance and the factors that contribute to its effectiveness. The freezing process in a cold room begins with the regulation of temperature. These rooms are equipped with advanced refrigeration systems that ensure a constant and controlled environment. By maintaining temperatures below the freezing point, the cold room creates an ideal condition for preserving food, pharmaceuticals, and other temperature-sensitive products. This temperature control is crucial as it inhibits the growth of microorganisms and slows down chemical reactions, thereby extending the lifespan of the stored items. In addition to temperature control, humidity also plays a vital role in the freezing process. Cold rooms are designed to maintain low humidity levels, as excessive moisture can lead to the formation of ice crystals and affect the quality of the frozen products. By controlling humidity, cold rooms prevent freezer burn and maintain the integrity and texture of the stored items. Proper airflow is another essential aspect of the freezing process in a cold room. Air circulation ensures uniform cooling and prevents temperature fluctuations within the storage space. This is achieved through strategically placed fans and vents that distribute cold air evenly. The circulation of air also helps in maintaining consistent humidity levels, minimizing the risk of condensation and frost formation. The duration of the freezing process depends on various factors such as the type and quantity of the product being frozen, the initial temperature, and the desired final temperature. It is crucial to follow specific freezing protocols to ensure optimal results. Rapid freezing is often preferred as it reduces the formation of large ice crystals and preserves the texture and nutritional value of the products.

Conclusion

The article highlights the factors that contribute to the freezing capability of a cold room. It emphasizes the importance of proper insulation, layout, temperature control, humidity management, and well-maintained equipment for maintaining an efficient cold storage system. It also mentions that cold rooms are not limited to storing food products and freezing alone, but they are integral to various industries, offering both freezing and refrigeration capabilities. The advancements in technology have made cold rooms more energy-efficient and environmentally friendly. Understanding the potential of cold rooms is crucial for making informed decisions in industries where temperature control is paramount. The article concludes by stating that understanding the freezing process in a cold room is vital for industries that rely on precise temperature control, as cold rooms provide a controlled environment that inhibits the growth of microorganisms and extends the shelf life of perishable items. By following proper freezing protocols and maintaining the optimal temperature, organizations can maximize the freezing capability of their cold rooms.

If you would like to learn more, please contact us at www.coldroomjl.com