COLD ROOM PANEL: EVERYTHING YOU NEED TO KNOW

Cold Room Panels: A Comprehensive Guide for Informed Choices

Cold rooms have become a staple in warehouses for storing materials with limited shelf life, such as fresh produce, meat, beverages and pharmaceuticals. Its main function is to keep fresh, which not only freezes food but also keeps fresh. While there are many different types of cold storage with widely varying temperatures, they all have some form of insulation installed to insulate them.

The refrigeration system in the cold room is responsible for achieving the preset temperature, and the insulation function of the cold storage is responsible for preventing the cold air from escaping!

Depending on the type of cold room and refrigeration system installed, users can modify their insulation features to achieve optimal results. One of the most common types of insulation used in cold rooms today is known as a cold room or insulation panel.

In essence, cold room panels are insulated panels made from two main components: a core and two structural boards. The shield of the rigid core is usually made of PIR or PU. On the other hand, the two structural plates responsible for housing the core are usually made of pre-painted galvanized steel (PPGI) or stainless steel.

They are also used in conjunction with foam insulation to help prevent cold air leakage and ensure the structural integrity of the cold room envelope. The entire panel is like a sandwich, so it is also called a "sandwich panel".

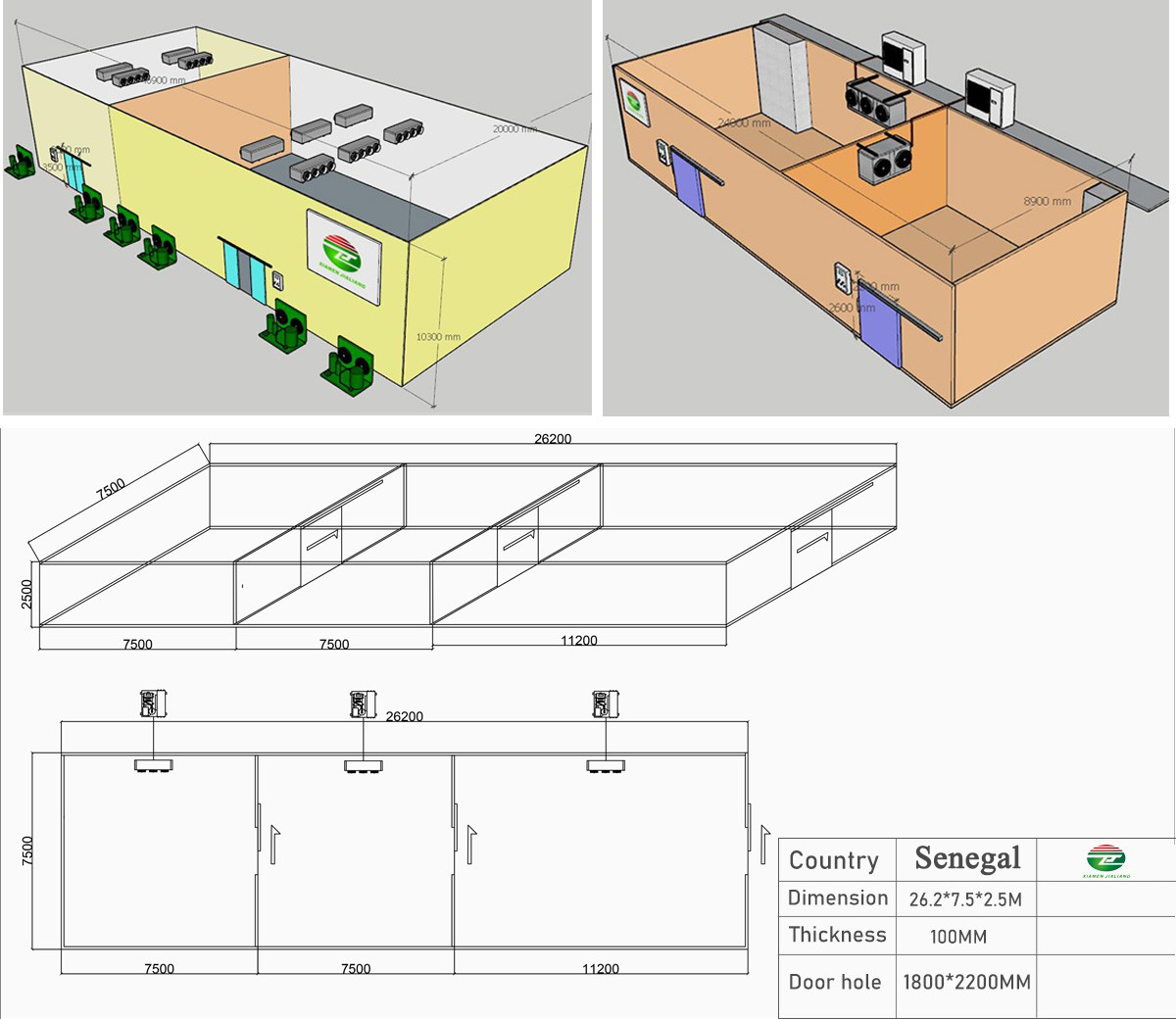

For the installation of cold storage, Jialiang (Jialiang) provides installation instructions (including installation diagrams), even novice engineers can easily complete the installation work~

Features of a Cold Room or Insulated Panel

Most commonly, cold room panels are manufactured piece by piece. This makes transportation and use more convenient. Most customers are transported in bulk and installed by themselves (if the project is difficult to install, engineers will be arranged to help). The thickness of these insulation panels can vary between 50mm and 150mm and is completely determined by the indoor and outdoor temperature and size of the cold room.

Experts recommend using it for initial construction. Not only does this reduce cost and effort, but it helps ensure the overall design and structural integrity of the cold room. In addition, if the cold storage is installed after it is built, many times the insulation board will not be able to perform at its best, which may cause cold air to leak.

Types of Cold Room Panels

There are different types of cold storage panels for users to choose from. However, these differ not only in application, but also in the type of cold room designed and installed. We commonly use PU panels.

Polyurethane insulation board

Polyurethane (PU) insulation panelsare one of the most commonly used insulation solutions in cold rooms, chillers and freezers. Their high heat resistance makes them an excellent primary insulation solution, especially for cold room projects that require quick assembly. These panels are installed using the tongue and groove system as it is the easiest and most effective for this type of panel.

How To Install a Cold Room or Insulated Panel

Installing cold room paneling primarily depends on the size and type of cold room being designed and set up. Depending on the type of panelling that you may opt for, there are user-friendly kits available with clear instructions regarding installation.

However, this is only possible for small-scale cold rooms, as industrial-grade ones will require an expert team for installation. Despite this, there are certain prerequisites necessary for installation:

l Pre-set insulation panels

l Measuring tape

l Allen Key

l Screwdrivers and applicable screws

In terms of installation, Jialiang will provide you with installation diagrams and video tutorials. If the project is more responsible, we will arrange engineers to help you, and we will try our best to provide you with the best service!

In Conclusion

cold storage panels not only help you achieve better insulation, but also increase the structural stability and integrity of your cold room. It exists to help complete projects!

If you want to know more about the product, please consult us. Our website is www.coldroomjl.com