Accurate Calculation and Installation for Efficient PUF Insulated Panel Cold Rooms

Cold rooms are commonly used low-temperature storage equipment in various industries, extensively utilized in fields like food and pharmaceuticals that require temperature-controlled storage. To ensure the effective operation of cold rooms, the selection of high-quality insulation materials is crucial to minimize heat transfer and maintain the desired temperature range. Polyurethane foam (PUF) panels have become a popular choice for insulation material.

This article explores the installation process of PUF panels in cold rooms and provides examples and calculation methods to help you better understand the process.

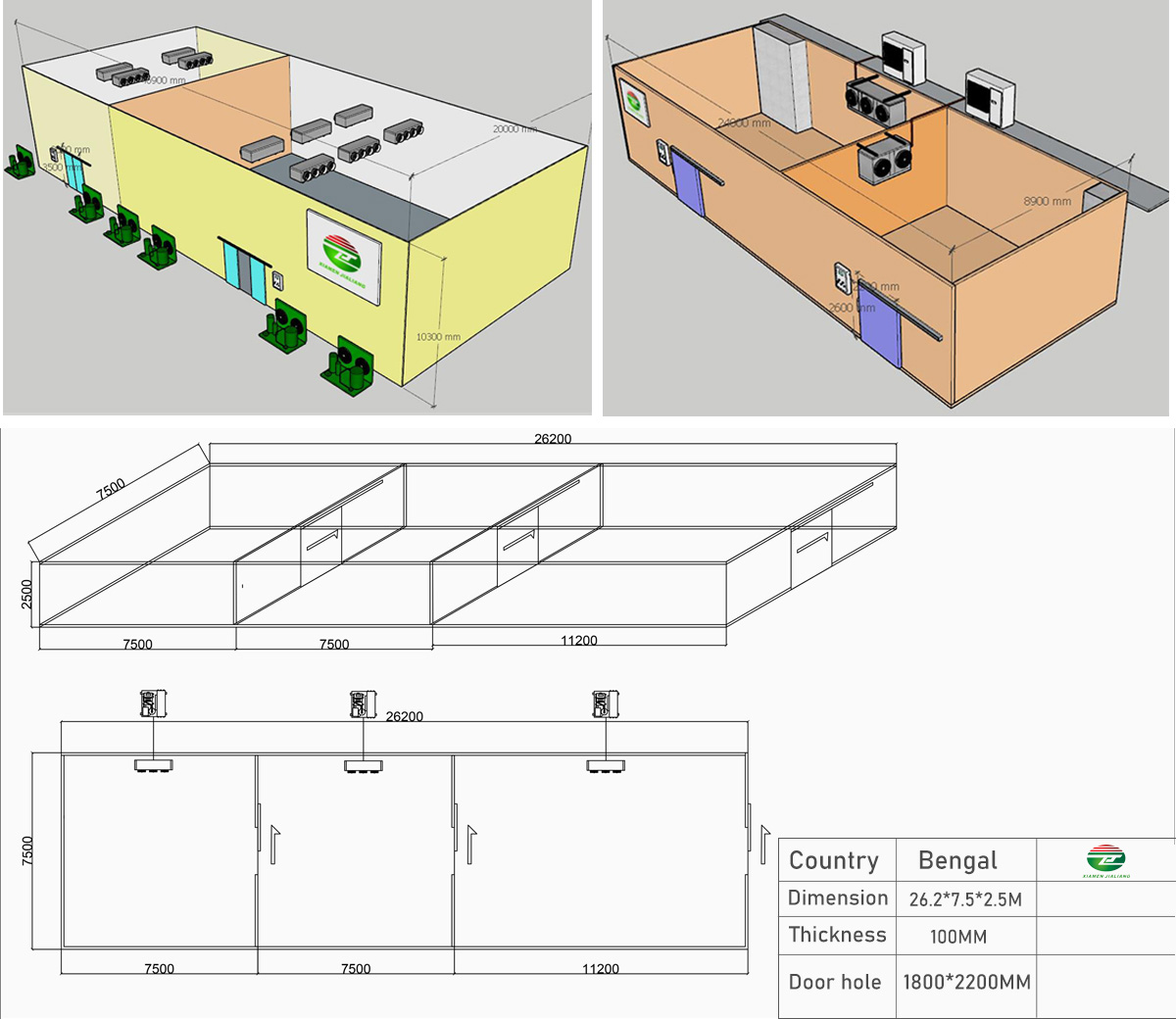

Step 1: Determine the Cold Room Size

The first step in installing PUF panels is to determine the dimensions of the cold room. This helps in determining the required coverage area of the materials. For example, let's assume the cold storage room is 8 meters long, 4 meters wide, and 3 meters high.

Step 2: Calculate the Surface Area of the Cold Room

Next, calculate the surface area of the cold room to determine the number of PUF panels required for installation. You can use the following formula to calculate the surface area:

Surface Area = 2 * (Length * Width + Length * Height + Width * Height)

Using the dimensions provided in step 1, the surface area calculation would be as follows:

Surface Area = 2 * (10 * 5 + 10 * 3 + 5 * 3) = 160 square meters

Step 3: Determine the Thickness of PUF Panels

The next step is to determine the thickness of the PUF panels required. The thickness of PUF panels depends on the desired temperature range and the expected temperature difference inside and outside the cold room. For example, let's assume the desired temperature range is between -18°C and -22°C, with an expected temperature difference of 20°C.

You can use the following formula to calculate the thickness of PUF panels:

Thickness = (Temperature Difference / K) * ln (Desired Temperature Range / External Temperature)

Here, K represents the thermal conductivity coefficient of the PUF panel, typically around 0.02 W/mK.

Using the values provided above, the calculation for the thickness of PUF panels is as follows:

Thickness = (20 / 0.02) * ln ((-18 + 273) / 293) = 0.12 meters (or 120 millimeters)

Step 4: Order PUF Panels

Once the thickness of the PUF panels is determined, the next step is to order the required quantity of PUF panels from a supplier. It is crucial to ensure that the selected PUF panels meet the requirements and have superior quality.

Step 5: Install PUF Panels

The final step is to install the PUF panels in the cold room. The installation process includes the following steps:

Ensure that the cold storage room is clean and free from any debris.

Install the base frame and support structure for the PUF panels.

Start installing the PUF panels layer by layer from the bottom, ensuring proper alignment and tight fit.

Fill any gaps between the panels with PUF sealant.

Install doors and windows using PUF panels and sealant.

Install the refrigeration equipment and test the cold room to ensure it can maintain the desired temperature range.

In summary, accurate planning and execution are essential for calculating and installing PUF insulated panels. By following the steps mentioned above and performing the necessary calculations, you can ensure effective insulation and maintenance of the desired temperature range in the cold room. Calculating the cold room size, surface area, and PUF panel thickness accurately, and selecting high-quality materials will allow you to create an efficient refrigerated environment.

Furthermore, attention to detail and quality control are important during the installation process. Ensuring a clean cold room helps avoid any unnecessary heat conduction. Properly installing the base frame and support structure provides stable support and correct panel alignment. Filling gaps between panels with PUF sealant prevents heat leakage. Additionally, using high-quality sealants and PUF panels for doors and windows ensures sealing performance and insulation effectiveness.

Finally, testing and commissioning of the cold room are crucial. Ensure that the appropriate refrigeration equipment is installed and conduct temperature tests to verify that the cold room can consistently maintain the desired temperature range. This ensures that the cold room achieves the expected insulation efficiency during actual operation and provides optimal storage conditions for the products.

In conclusion, calculating and installing PUF insulated panel cold rooms require comprehensive consideration of factors such as size, surface area, and thickness while following professional installation procedures. By accurately calculating, selecting high-quality materials, following proper installation steps, and conducting necessary testing, you can create an optimized refrigerated environment that achieves effective insulation and temperature control. This will provide a reliable storage solution for your business, preserving the freshness and quality of the products.

For more information of translation, please visit www.coldroomjl.com.